How Masonry Contractor can Save You Time, Stress, and Money.

Mortars kinds are normally Kind M, S, N or O. A standard understanding of these mortar types is useful. All mix amounts given below are quantity proportions (instead of weight proportions). Kind M mortar is the greatest strength (2500 psi typical compressive toughness at 28 days) as well as is commonly utilized for below quality frameworks such as structures wall surfaces and storm water structures.

Type S mortar is the next highest possible in strength (1,800 psi ordinary compressive stamina at 28 days) as well as is the basic purpose high stamina mortar. It often tends to be the highest expense of the mortar blends and has proportions of 1 component Portland Cement, 1/2 component lime as well as 4 1/2 parts sand.

Some Known Details About Masonry Contractor

Kind O mortar is a reduced stamina mortar (350 psi ordinary compressive toughness at 28 days) made use of just for non-load bearing indoor wall surfaces. It is the most affordable cost mortar with mix percentages of 1 component Portland Cement, 2 components lime as well as 9 components sand. It is rare to see Type O mortar defined, yet it is allowed to make use of per the International Building Regulations 2006.

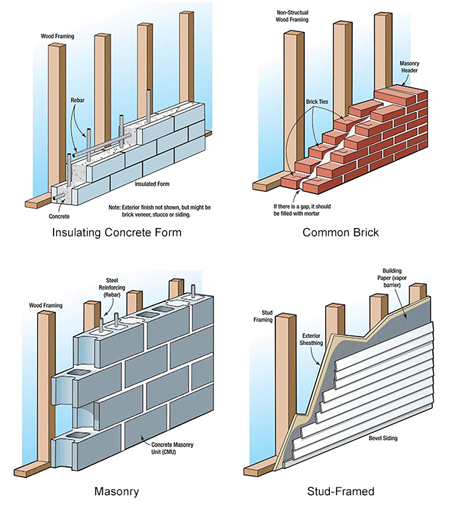

Low lift grouting is a basic approach of positioning cement at scaffold elevation (prior to constructing the following lift of scaffold) or bond light beam height. Vertical rebar, if called for, are often positioned in the cores after grouting as well as mixed to assist combine the grout. The bar lap for the upright rebar is commonly a minimum of 30 bar diameters.

High lift grouting, on the other hand, permits the Masons to grout the wall for the entire tale (up to 24') and also is more complicated - masonry contractor. The dimension of the open vertical cells requires to be assessed and 3" x 4" clean out openings at the end of the grout lift must be made use of.

Rumored Buzz on Masonry Contractor

With either grouting technique, making certain grout in fact loads the wall surface gaps assigned to be loaded is a location typically missed on job sites. There must be a technique concurred upon for filling up wall spaces that guarantees the cement obtains all the method to the bottom. The Construction Manager should be aware of the chance of failure around and informative post take actions to see to it the process is done correctly.

html. Control joints are made use of to eliminate masonry tensile stress and see it here anxieties as well as enable movement to occur. Normally a pre-formed rubber gasket is used at vertical control joints to transfer the shear load (normally wind tons) across the joint yet still allowing the joint to move horizontally. Stonework control joints ought to be displayed in Contract Papers.

This is really vital as when these bricks are used with concrete mortar, we ought to thoroughly soak them before laying. Only when fat lime or clay mortar is utilized or when one is forced to make use of blocks that are not well scorched, this saturating guideline has to be kicked back.

Just how do you build a stonework wall surface? A layer of mortar is spread to cover the full width of the wall for a suitable length of the reduced training course.

Masonry Contractor for Beginners

Lastly, we push the side bulging mortar in firmly to be level with the face of the wall surface if it is to be left unplastered. In the common method embraced by many masons, a row of blocks is very first put on a thin layer of bed mortar leaving the cross joints vacant.

Purely this is not an excellent practice. (However, when making use of cement mortar of high stamina, the loss of toughness due to infraction of these regulations may be just marginal.)The wall surfaces are increased truly plumb. All training courses are laid really horizontal and also all upright joints truly upright. Vertical joints in alternate programs need to come straight, one over the other.

For this function, a wood straight edge with graduation giving a density of each brick course including joint can be used for support. For a thick wall, the above operation is duplicated together with both faces of the wall and the indoor loading blocks find more info for the thick wall are stocked a comparable manner. masonry contractor.

This operation of filling up open joints is described flushing-up. It is wrongly left out for a number of courses on some badly-executed work as well as only done afterwards (not after every course) in an ineffective fashion. It is not a great method and needs to be stayed clear of as it is important that every course should be purged approximately the degree if great job is required.

Comments on “Not known Incorrect Statements About Masonry Contractor”